About Us

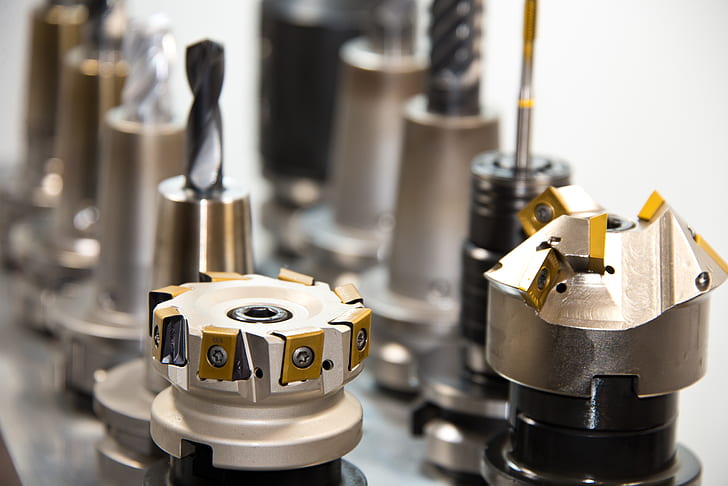

Since its inception, Shiv Shakti has focused on advanced carbide cutting and wear solutions, delivering quality-driven products for diverse industrial needs

Get a free quote

Contact Info

- Pune, Maharashtra – 412105

- +91 88055 84273

- info@shivshakticutting.com

Sustainability

- Home

- Sustainability

Sustainability at Shiv Shakti Enterprises

At Shiv Shakti Cutting and Hard Material Solutions, sustainability is not an option — it is a responsibility. We are committed to supplying high-performance cutting and wear-resistant solutions through trusted sales and authorized dealership, while minimizing environmental impact through recycling and efficient resource utilization.

Our approach integrates advanced material technologies, circular economy principles, and product carbon footprint transparency to support modern, sustainable industrial applications.

Circular Economy & Material Recycling

Recycling and circular material use play a vital role in conserving natural resources and ensuring long-term supply chain stability. By reprocessing valuable hard materials such as tungsten carbide, we significantly reduce waste and dependence on virgin raw materials.

- ✔ Reduced raw material consumption

- ✔ Lower environmental impact

- ✔ Stable and resilient supply chains

- ✔ Consistent product quality

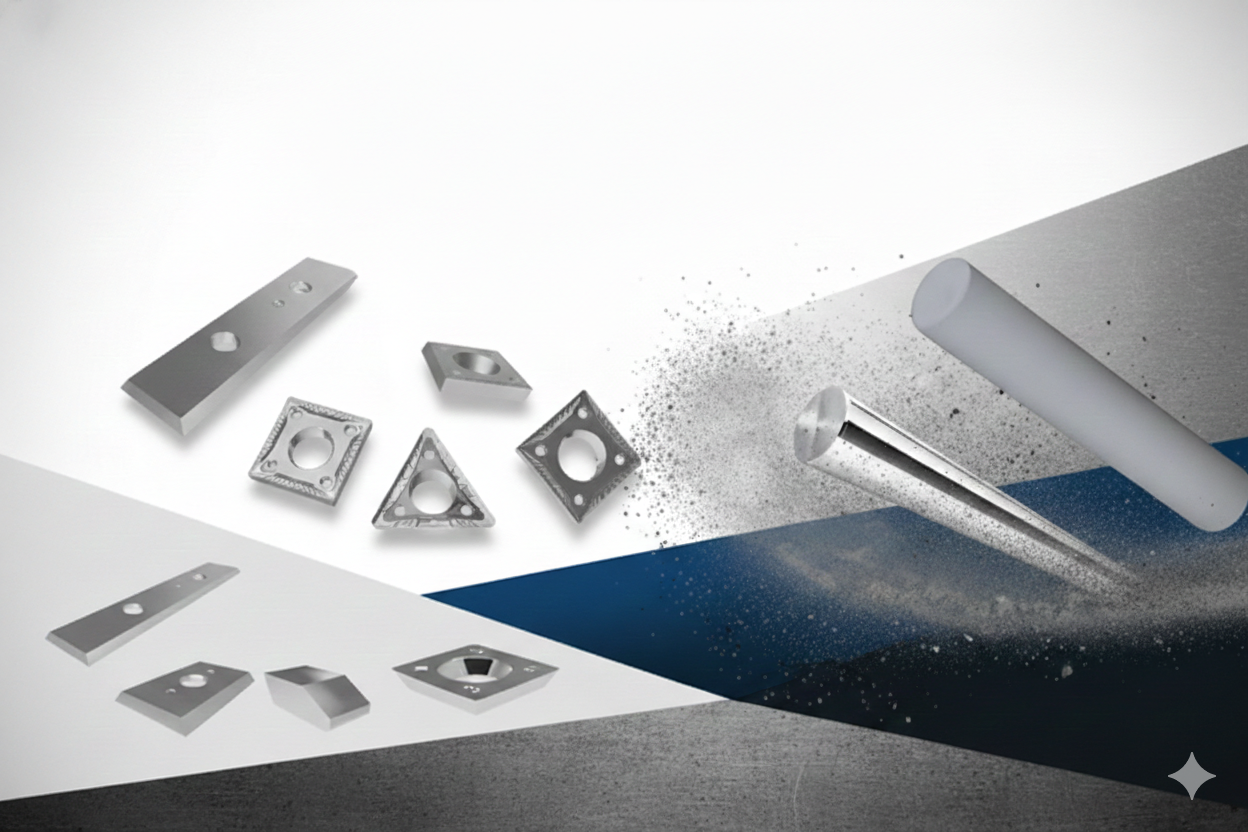

Reprocessed Carbide Materials

Our recycled and reprocessed carbide materials are engineered to meet demanding industrial standards without compromising performance.

- ✔ 50–99% reprocessed carbide content

- ✔ High material recovery with minimal waste

- ✔ Low CO₂ emissions compared to conventional grades

- ✔ Performance equivalent to premium carbide

Applications

- ✔ Cutting tools

- ✔ Indexable inserts

- ✔ Carbide rods

- ✔ stone-processing tools

Why Sustainable Carbide Matters

- ✔ Consistently high cutting performance

- ✔ Optimized tool life and wear resistance

- ✔ Reduced carbon footprint

- ✔ Improved resource efficiency

- ✔ Long-term cost benefits

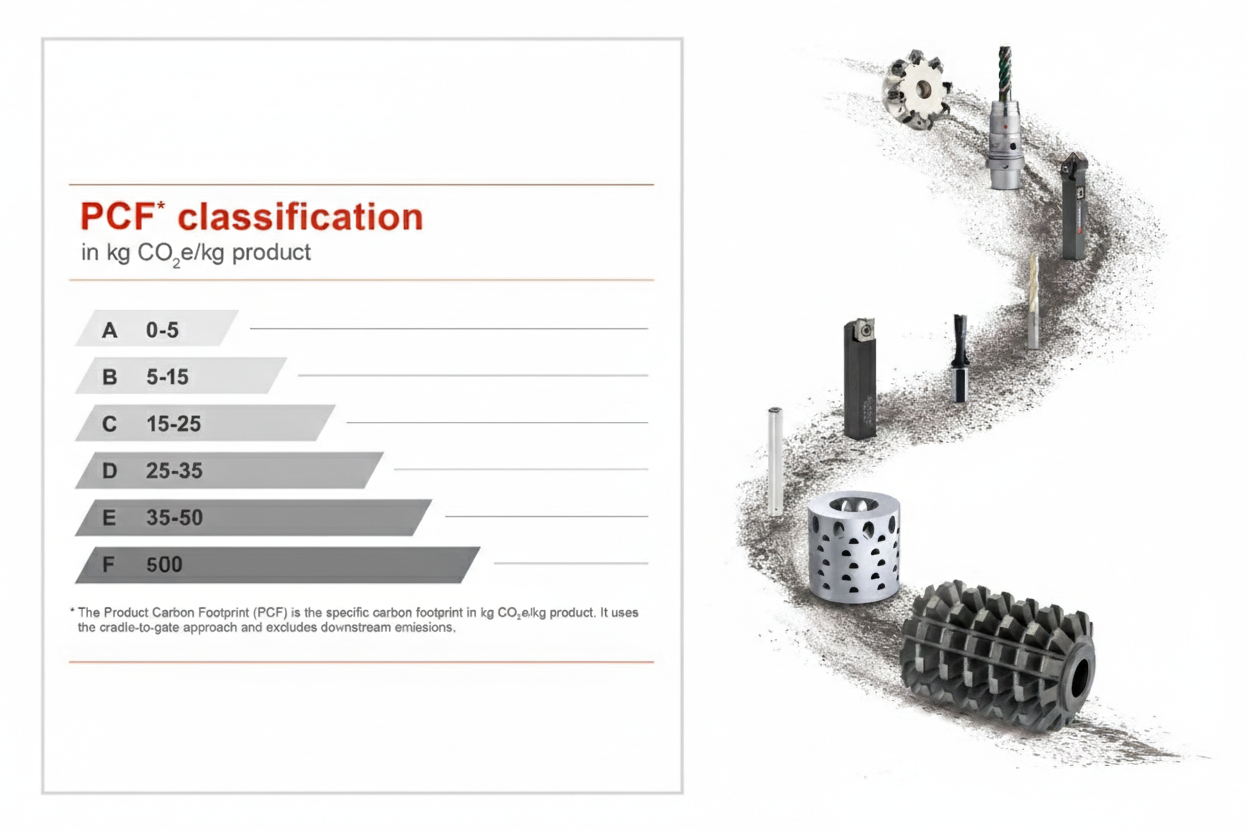

Product Carbon Footprint (PCF)

To provide transparency and enable informed decisions, Shiv Shakti follows a Product Carbon Footprint (PCF) methodology that represents total CO₂ emissions per kilogram of product.

- ✔ Raw material sourcing

- ✔ Trusted Sales & Authorized Dealership

- ✔ Energy consumption

- ✔ Waste and recycling efficiency

Our calculations follow ISO-based standards and a cradle-to-gate approach, focusing on emissions up to product delivery. Our low-carbon recycled grades can reduce CO₂ emissions by up to 60%.

Our Commitment to a Sustainable Future

- ✔ Recycling and regrinding technologies

- ✔ Energy-efficient production methods

- ✔ Environmentally responsible sourcing

- ✔ Continuous sustainability innovation

We believe high performance and sustainability can go hand in hand — delivering reliable cutting solutions today while protecting resources for tomorrow.

Upgraded Sustainable Product Grades

Our upGRADE product range represents a new generation of sustainable carbide solutions, engineered using advanced recycling technologies with a significantly reduced environmental footprint.

Regrinding upGRADE – Woodworking

KLC20+ grade uses a minimum of 99% reprocessed carbide powder, ensuring long tool life and excellent cutting precision.

- ✔ Optimized for woodworking tools

- ✔ Reduced CO₂ emissions

- ✔ Excellent wear resistance

upGRADE – Carbide Rods

CT-GS20Y is developed with at least 99% recycled carbide powder, delivering the lowest carbon footprint in its category.

- ✔ Stable microstructure

- ✔ Consistent quality

- ✔ Suitable for cutting tools & wear parts